|

By Richard Beach Richard Beach is a seasoned goldsmith with decades of laser welding experience. You can watch Richard live on a laser welder at JCK 2022 Las Vegas at the Sunstone booth. The secret to realizing a healthy profit from repairs is efficiency. You’ve heard the old adage that “time is money,” and with repairs it’s never been more true. The faster you can complete a repair, the more profitable the service is to your store.

A true craftsman knows the importance of having the right tools. For repairs and restorations, a benchtop laser welder is paramount, and here’s why: 1. Pinpoint Accuracy The laser welder in my store, an Orion LZR 100, provides 0.2 mm of focus, meaning repairs can be made in the tiniest of areas. I can fix filigree, channels, prongs, and chains with pinpoint precision. I can’t imagine taking on the responsibility to restore the family jewels and not have pinpoint accuracy. 2. Speed and Efficiency Not to brag but rather to set an efficiency baseline, I’ve tipped 40 prongs start to finish in less than 30 minutes. To use a torch, that kind of job would require hours of time and, in the end, I would lose money. Another example: Laser polishes the workpiece as you work, which makes clean up a breeze. And—you’ll like this—the use of such a high tech machine justifies the rush charge on those “I need it in an hour” jobs. Simply put, the laser welder is not an expense, but a money maker. 3. Work Effortlessly with Castings Every bench jeweler has experienced that job that had to be done no matter what. And then, when you get into the job, you realize you only have a partial casting, or voids, porosity, missing prongs, or all of the above. All of these issues are easily fixed with a laser welder. 4. Do the Impossible Remember the family heirloom that turned out to be nothing more than costume quality? And you promised to fix it? No problem! I’ve fixed many a piece that before having a laser welder I would have turned down. I rarely turn away any repair and have gained gratitude and customers for life. 5. Profitability Anytime you can do a job quicker, easier, cleaner, and with less effort, you put money in your pocket. The ROI is measured in weeks and months, not years. Some quick, back-of-the-envelope math will show you how much repair work you need to add to your store to justify a laser welder. And you’ll be surprised by the numbers. It truly pays for itself from day one.

8 Comments

By Andy Jensen The fashion, jewelry, and tattoo industries are ever-changing stages for new trends. One that has recently caught fire is permanent jewelry, and people are lining up to have a chain of gold, platinum, or any type of metal permanently welded around their wrist or ankle.

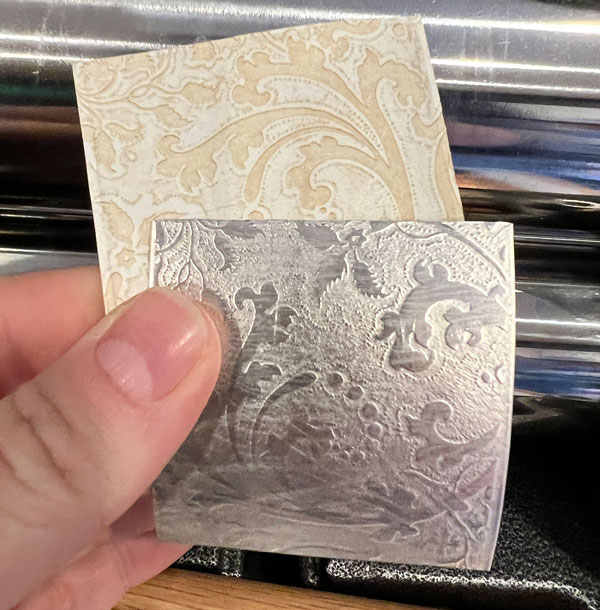

The permanency begs two questions: How do you permanently attach a chain? Why would you want to? Let’s tackle the first question. In the permanent jewelry world, an open chain link is used to connect both ends of the chain and then welded together. Unless you break or cut the chain with wire cutters, it’ll stay attached forever. Now, for the second question: Why? For all the same reasons that drive us to be unique, daring, and bold. A permanent bracelet can remind you of love or friendship; it’s like a wedding band that never comes off. Coco Chanel, the iconic fashionista of the 1900’s said, “In order to be irreplaceable, one must be different.” You can bet Coco would be first in line for her permanent bracelet. The permanency is the main attraction, but there are two additional benefits to permanent jewelry. With no clasp, the jewelry will never get hung up on clothing, nor ever become inadvertently unclasped and lost. When you replace the clasp with a solid welded link, you never have to worry about losing something dear to your heart. Demand is strong. A Tik Tok search indicated more than 161 million views, and that’s just one social media platform! Unarguably, it’s a trend that is gaining speed. The demand is there, but how do you get started? The Secret Permanent Jewelry Tool With an Orion pulse arc welder you can close a chain in the blink of an eye. The welder has a tiny footprint, uses a normal electrical outlet, requires little training on the part of the artist, is harmless, completes the job in a fraction of a second, and is surprisingly affordable. The Orion pulse arc welder is a micro welder, so think tiny. Using electricity, the welder will heat, melt, and join the two ends of a link together forever. The heat is localized to a very small spot and can be touched without harm just seconds later. How It can Work in Your Studio The first thing that happens is your customer selects a chain. You measure out and cut the correct length, which will leave an open link on the chain. Place the chain around the customer’s wrist or ankle. Using pliers, close the ends of the link together, then touch the ends with the tip of the electrode to weld it closed. The Business Model Explained The entire process, from choosing the chain to closing the sale, is measured in minutes. How much can you charge for a permanent bracelet or anklet? That depends on the type of chain, but you should be able to charge $30-$150 for a bracelet. If you average only five permanent bracelets per day, you’ll generate $150 on the low end and $750 on the high end every day. That’s a significant new source of revenue and a quick return on your investment in the Orion pulse arc welder. Watching Out for Customer Safety When it comes to customer safety. Avoid plated finishes, such as white gold with rhodium plating, which will rub off over time. Solid metal chains are more suitable. The chain design also matters. Stick to simple designs as more complex designs will require more welding, more time, advanced skills, or all of the above. Best to keep it simple. High karat golds, like 18 karat and above, may be too soft for a fine chain intended to be worn indefinitely. Ten karat and 14 karat alloys, on the other hand, are better options as they are less likely to tarnish and are more durable. As the operator, you’ll be viewing the welding process through an ADL, or auto darkening lens, that protects your eyes from the light coming from the weld. Watching many welds without protection can damage your eyesight. For your customer, you may want to ask them to don a pair of UV protective lenses, and you’ll want to instruct anyone who may be watching to look away during the weld. Your customer should choose a chain that won’t break during normal wear and tear; however, should that chain get caught in a door or in machinery, they do want the chain to break and spare them injury. One more thing: If your customer ever requires an MRI, all jewelry must be removed. The Right Equipment For permanent jewelry the Orion mPulse and Orion 100c will provide all the energy you need: About five joules for fine chains. Each model uses a touchscreen interface. Simply use your finger to increase or decrease energy levels. The mPulse and 100c are available with microscope options, which is great for small chains because, quite frankly, you can’t weld what you can’t see. The optics replace the ADL and allow you to be much more accurate in placing the weld. Plus, the optics are mounted to an articulating arm, which can be swung out of the way. You can add the optics for a nominal fee. Pulse arc welding requires argon gas. Argon is an inert gas; it’s non-flammable, non-toxic, has no smell, no color, and exists naturally in the atmosphere. The argon acts as a shielding agent during the weld, preventing messy oxidation, leaving a cleaner weld. To make a simple business idea even more simple, Sunstone offers a permanent jewelry kit that includes everything you need to get started: Welder, gas, UV safety, pliers, leather skin barrier, and starter chain. With the kit you can offer your customers a permanent jewelry solution the same day it arrives. By Melissa Muir When making jewelry, I prefer to create pieces that are a bit different from traditional jewelry. I call my particular style “wearable art jewelry.” In the case of creating a pendant using two different types of metal, I want to illustrate not only traditional jewelry making techniques, but how I also mixed in pulse arc welding. My work tends to use a variety of metal, including gold, sterling silver, and even copper. Two of the most difficult metals to weld are silver and copper due to their conductive properties. The welding task becomes even more difficult should you wish to weld the two together due to copper and silver having conductive properties and melting temperatures that are worlds apart. Join me as I walk you through the entire process—from planning to finishing—of this swinging pendant made from copper silver. The design I chose makes traditional soldering methods difficult if not impossible. I am creating a hollow form with a design that encapsulates a large rose cut labradorite cabochon. If the stone is set, the top cannot be soldered into place. And if the top is soldered into place, the stone cannot be set. Typically, this piece would have me employ a cold connection mechanism. As you will see, a welder will solve this problem for me as well as simplify the job of attaching the swinging bail. A welder provides the perfect final touch: Two perfectly formed balls locking the bail into place. I start off by choosing the stone and a silhouette die that will give me the shape for the pendant. A silhouette die, as seen in Figure 1, features a shaped void in the center where metal can be pushed in to form a sort of pillow or embossed shape. Here I have chosen a stylized square and round rose-cut labradorite cabochon. Using the die as a guide, I draw up several different design ideas and settle on one for the final piece. The design is transferred to the metal using a pen and pencil, which will act as a guide for engraving and piercing but does not have to be exact (see Figure 2). Figure 1. Silhouette die and labradorite cabochon. Figure 2. Design transferred to metal. In Figure 3, with the metal mounted and secured to a ball vise, you can see I use a graver to flare cut the design into the front of the piece. Figure 3. Using engraver to fare cut the design. Using the laser cut pattern from Rolling Mill Resources you see in Figure 4, the back piece is run through the rolling mill to provide the pendant with additional detail. Figure 4. Adding detail using laser cut pattern from Rolling Mill Resources. The metal is taped into place on the silhouette die to keep the pattern in the desired position (see Figure 5). The die is then placed into a container along with a piece of urethane and steel pusher. The entire stack is then centered over the ram of a hydraulic jack in my press manufactured by Potter USA. I will repeat this process for both pieces applying about 2,000 pounds of pressure. Figure 5. Using a Potter USA hydraulic jack to press pattern to the metal. Next, in Figure 6, using a jewelers saw, both pieces are cut out around the perimeter of the square shape. In addition, I cut the windows into the top piece using the engraved design as a guide. Due to the shape of the back plate, the bezel for the stone needs to be modified so it can be soldered into place securely. Sandpaper rolls come in very handy for this task as I can gently smooth away and form the bezel to fit properly (see Figure 7). The bezel is then soldered into place on the backplate. Figure 6. Use jewelers saw to cut out the background. Figure 7. Smoothing the bezel for a correct fit. After a quick test fit of all the pieces (see Figure 8), I use a rubber abrasive to clean up any extra solder and polish the inside of both the top and bottom, which you can see in Figure 9. The design dictates that all this must be done before the two halves are welded together. Figure 8. Checking for fit. Figure 9. Cleaning up extra solder. To create a strong join, both pieces must have a good connection, similar to when soldering a bezel or ring. As you can see in Figure 10, I place a piece of 320 grit sand paper on a flat surface and rub both pieces to create a flat spot around the edges. Figure 10. Creating a flat surface to create a stronger joining. Before I can weld the two pieces together, the stone must be set. I like to secure the piece in thermolock as seen in Figure 11, or some other fixturing compound to hold it steady. The stone can then be set with traditional bezel setting tools or a hammer handpiece. Figure 11. Setting the stone. Now, I’ll find the right weld settings for the materials I’m using. For this job I’m using the Orion 200i pulse arc welder from Sunstone, because the welder’s software walks me through the process of finding near-perfect settings. I start by selecting silver for the type of metal. Moving into the ARC screen I change a few settings:

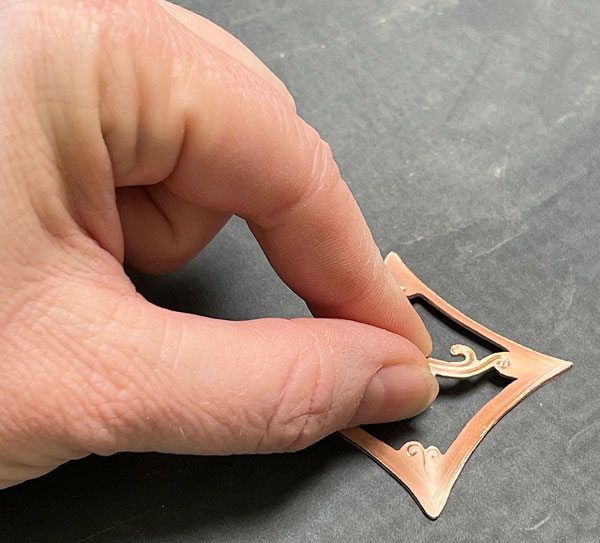

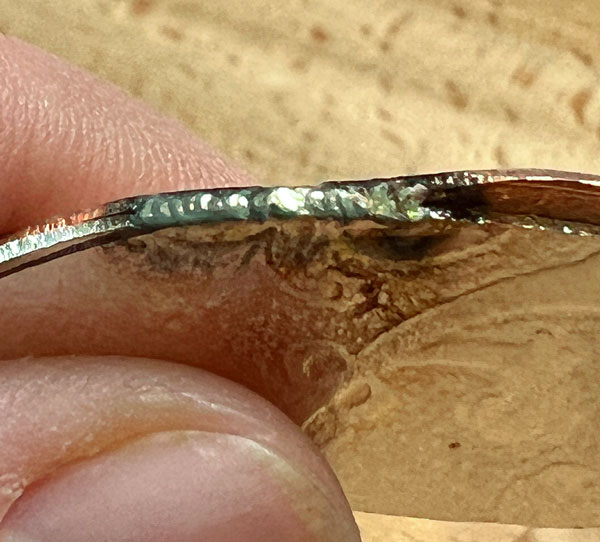

Using scrap pieces which you see in Figure 12, I test the weld and make any necessary adjustments. (I like to use the cutoffs from the front and back to ensure that I am working with the same exact materials and thicknesses.) I want to see an even seam where there seems to be just one piece and not two. Once I am certain the settings are good for a proper join, I move to tack weld the center of each side on the pendant. Figure 12. Testing different weld settings on scrap metal. Wearing leather gloves, I hold the piece and begin to weld one side of the pendant, making sure the electrode is touching both sides of the seam. As the piece warms up, I notice the seam becomes a little uneven and begins to have “splatters” and “drips” as you can see in Figure 13. The splattering and dripping are caused by two different factors. First, the electrode is beginning to become coated by the spattering of copper and silver, which affects the flow of energy through the electrode. Secondly, the piece is too warm for the amount of energy I’m using. Figure 13. Weld splatters and drips. When welding copper and silver, I blunt the end of the electrode ever so slightly (see Figure 14), which helps the energy spread across the piece just a little. With a clean electrode and a change of energy down to 60 Ws, the seam is smooth, and, as you can see in Figure 15, I am left with a perfect weld bead on the edge of the piece. Figure 14. Blunting the electrode to spread energy across the workpiece. Figure 15. Better welding results with a blunted electrode. And now for the real test: Cleaning up the seam, which will clearly show if the weld is deep and solid. Because the form has an inward curve, I use a half round file to clear away as much of the metal as possible and even out the surface. (see Figure 16). If there are any pits, now is the time to fix them. If necessary, I use silver wire to add a little bit of metal to build up and smooth out the pits. Following the file, I use a sandpaper roll, then a silicone wheel, and finish with a soft cotton buff and polishing compound. Figure 16. Cleaning up the seam. Finally, I need to make the bail. After deciding the shape, which you can see in Figure 17, I engrave a complimentary design and pierce it out with my jewelers saw. Before shaping, I measure and drill a hole at each end for the hinge pin. I use my ring bending tool from Durston Tools to bend it into a horseshoe shape. Figure 17. The bail laid flat. Using the hinge as a guide, I mark and drill a hole in the top of the pendant (see Figure 18). The wire I am using for the hinge pin is 0.8mm (20 gauge), so I use a 1.0mm drill bit for the holes. Figure 18. Bending the bail. Setting the welder to 6 Ws, I touch the end of the hinge pin wire to the tip of the electrode to form a small, perfectly round ball, which you can see in Figures 19, 20, and 21. I will typically repeat this at least once or twice to enlarge and straighten the ball if necessary. Figure 19. Balling up the end of the hinge pin. Figure 20. Using the pulse arc welder to ball up the hinge pin. Figure 21. Closing the hinge pin with another ball using the welder. I will feed the pin through all holes capturing the pendant inside the bail. Once the wire has gone through all layers, I cut it to length, about 1/4” long, and repeat the balling process on the other end of the wire, effectively creating a hinged bail. As a final step, I remove any soot with the fiberglass brush and polish everything one last time with the soft cotton buff and polishing compound. The finished pendant speaks volumes about how much more creative I can be with a pulse arc welder. And not any welder; I’m familiar with the two major pulse arc welder brands. The Orion 200i provides the energy control I needed for a successful joining of silver and copper. When you take a close look at the edge of the pendant (see picture below), you can clearly see how the welder melded the two metals together, which I find impressive. About Melissa Muir

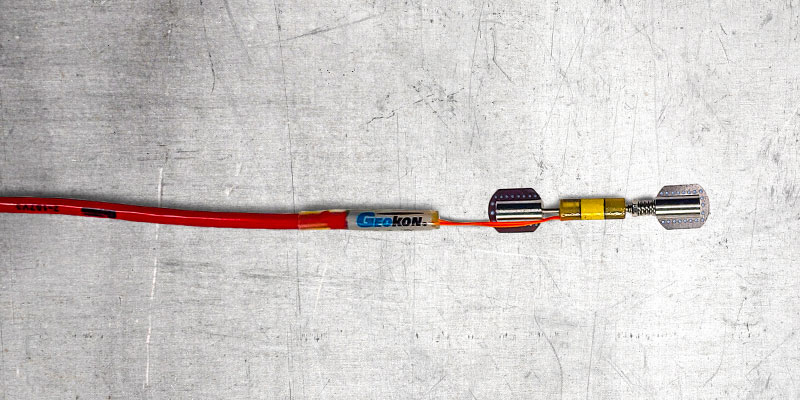

For more than a decade, Melissa has used her skills as a talented educator to help thousands of people become more knowledgeable about tools, their uses, care, and maintenance. She works with some of the largest names in the industry as she shares her knowledge and love of various metalsmithing techniques and tools. Micro Welding in Far-Removed or Hard-to-get-to Worksites Strain gauges can create as much stress as they measure. Designed to record or detect stress or force being applied to bridges, tunnels, wind turbines, or other load-bearing structures, oft times engineers are attaching strain gauges in places far removed from the nearest electrical outlet or in spots that are difficult to access. Moreover, temperature conditions may require gauges to be welded to key components rather than attached using epoxy.

When strain gauges are attached using a fine spot weld, usually less than one millimeter in diameter, remote work areas may not have power for your run-of-the-mill micro welder, like a Sunstone CDSP welder. Or, the work area may be difficult to access, such as at the top of a wind turbine or communications tower. In those instances, engineers are turning to the Sunstone Scout, a battery-powered, micro welder. The Scout packs 100 Ws of power, more than enough energy to attach a strain gauge or work with other electronic devices. With a single charge the Scout will deliver up to 2,000 welds and recharges in six hours. “The Scout serves a unique niche in civil engineering,” says Thane Kennedy, product manager at Sunstone. “For those times when you need a tiny weld in a tight spot, the Scout is the perfect solution. In Australia, for example, energy companies are taking the Scout into the bush. It’s small enough to throw into the back of truck, helicopter, or bush plane.” Weighing in at 11.4 kg, the Scout can be attached to a utility belt or safety point using it’s unique, center handle. Operators will also appreciate the Scout’s storage compartment, which keeps hand attachments and cables safely tucked away when not in use. To promote the Scout’s remote appeal, Sunstone produced an entertaining video that turned heads for its creativity and cinematography. Product Spotlight Sunstone Pico DC and Micro E By Andy Jensen Once upon a time, the last chore of my day was to charge my phone. I’d struggle to find the charging cable amid a jumble of cables, books, and glasses and then struggle again to fit the end of the cable into my phone.

That was then. The now story is I place my phone on a charging pad and I’m done. I can place my wireless ear buds on the same pad and charge them, as well, which is a bonus. Wireless power technology is projected to grow at 60% CAG through the 2020’s, according to New England Wire Technologies, a New Hampshire-based wire manufacture founded in 1898. Sales of wireless power technology is expected to reach USD $22 billion. While the scientific principle of wireless charging technology has been around since the 19th century, the introduction and use of Litz wire has turned principle into profits. Litz wire is comprised of many, very thin strands of insulated wire weaved or twisted in a specific pattern. The pattern is key to how Litz wire minimizes loss from the skin effect and proximity effect. Overcoming the Skin and Proximity Effect The skin effect refers to the behavioral tendency of AC power to accumulate and travel on the peripheral edge of a wire, leaving the center nearly unused. As a result, the flow of power becomes congested, creating resistance. The Litz wire pattern directs the power to use wire more efficiently, thereby increasing capacity. Compared to other wire of the same diameter, Litz wire can be 20 times less resistant, an outcome that catches the attention of electronics manufacturers. The proximity effect can also increase resistance by a factor of ten. In short, when current flows through a conductor, the current distribution will be constrained to smaller regions and thereby experience more resistance. Because a wireless power device is comprised of one or more conductors, the proximity effect poses a challenge to the device’s efficiency. Litz wire resolves the challenges posed by the skin and proximity effects due to each strand of wire being insulated from the other. The individual insulation and pattern was a game changer. Litz Wire: Every Rose has its Thorn Three cheers for Litz wire! However, connecting Litz wire to a PCB board is another matter. Sure, with enough solder and a steady hand, the insulation from each wire can be melted away, leaving the wire firmly connected to the board. But soldering sucks. It’s hot, toxic, dirty, slow, and inefficient. In the R&D lab, soldering makes sense. On the production floor, soldering is a profit killer. Welding eliminates the toxic and dirty conundrum, is significantly faster, and a process that neatly fits on any assembly line with added digital control. Litz Wire Conquerer: The Picó DC The ability to weld a Litz wire to a PCB board or other connection is possible with at least two other micro welding manufacturers. Avio and Amada both offer a welding configuration that will produce a satisfactory weld. Both companies introduced their systems long before wireless power started to become a thing. Sunstone’s recent introduction of the Pico DC is a more modern and less expensive solution than the others. The Pico’s eight-inch color touchscreen interface may be reason alone for a manufacturer to prefer the Pico over the others. But when paired with Sunstone’s new Micro E weld head, the Pico monitors real-time displacement and force. When you factor in price, the Pico stands as a clear winner. Sunstone reduced the cost of the Pico by combining all components into one unit, in addition to the weld head. The Avio and Amada configurations require multiple independent components, plus the weld head, which nearly doubles the price. “The Pico’s closed-loop feedback, force, and displacement technology makes it an attractive welding solution,” says Jonathan Young, president of Sunstone Engineering. “In a fully automated environment, the Pico will significantly contribute to a manufacturer’s quality control efforts and save on capital equipment costs.” Litz wire isn’t the only material the Pico seems to conquer with relative ease. Manufacturers who work with solar cells, PCB’s, magnet wire, coil terminations, electronics, heating elements, or fine ribbon bonding will find the Pico exceptionally valuable to their production processes. The Evolution of Benchtop Laser Welders Dave Holloway Not that long ago, purchasing a laser welder would set you back USD $40,000 or more. In those days, laser welders were large, pedestal-style machines that offered a maximum output of only 75 Joules of weld energy. Despite the large space requirements, the high price tag, and 75 Joule max-power output, early adopters with the means to purchase one of those welders will tell you that “buying a laser welder was the best investment I ever made, and I only regret I didn’t buy it earlier.” Sometime around 2007, laser manufacturers started building benchtop units designed to fit on a tabletop. The benchtop revolution produced smaller, lighter, and more affordable units than the pedestal laser welders. The space-saving features did have their trade-offs, though: The first benchtop welders had a max-power output of 25 Joules. You might be thinking, ‘who would buy such a unit? It only has 25 Joules?’ But your initial thought would be mistaken. Benchtop units revolutionized the laser welder market, similar to how tablet and laptop computers have replaced the larger, immobile desktop PCs. Few, if any, complained about the low power output of only 25 Joules. Instead, they gushed about the compact design, and somehow, 25 Joules gave them enough power to make the welds they needed to make. Let us fast forward to 2021. If you go shopping today for a laser welder, you can still find some pedestal-style welders, but most laser welders will be a benchtop model. Prices have come down considerably while the max-output power has dramatically increased. If buying a 75 Joule pedestal laser for $40,000 was the best investment some ever made, it is a wonder that people today balk at a laser welder at a considerably lower price. For example, at the time of writing, Sunstone offers a 75 Joule benchtop welder for $14,900. What a steal! But let me acknowledge that $14,900 is still a significant amount of money, and everyone I know has more than just a laser welder on their wish list. Even with all the reasons to buy a laser today, for some, it might not be the right timing, or it might not fit the budget, or there might not be enough space to house the laser. If you can relate to the hurdles of budget or space limitations, you may be in luck! Technological advancements are constantly driving prices down while simultaneously expanding feature sets. Introducing the Budget Laser Welder The first actual budget laser welder, the Dado, came to market in 2019. The development process of the Dado was a bit unusual. Rather than starting with a list of features, capabilities, and competitive analysis, and then establishing margins and a retail price, this development project began with a target retail price and then worked backward, incorporating as many features as possible while still maintaining the target retail price. The Dado is not the flashiest welder available, nor does it have a never-ending list of features, but it is an awe-inspiring machine considering how much it offers for how little it costs. In the first year of sales, the Dado quickly exceeded sales projections. Even though the target customer was the small shop that could benefit from laser welding technology but that previously could not justify the expense, big-name companies also jumped at the opportunity to buy a Dado welder. These big companies exponentially increased the number of laser welding stations in their facilities, for a minimal investment. In short order, larger companies significantly reduced production costs thanks to the Dado. The Competition Fires Back In response to the Dado’s success, other budget laser welders entered the market soon thereafter. Orotig S.p.A., an established player in the laser welder market, introduced the MiDi and the Neutec PulsePoint™ Studio™ Plus 25, two budget laser welders designed to compete with the Dado’s price and small footprint. How do they stand up to the Dado? While the MiDi and PulsePoint Studio have sold well, they fall short in beating the Dado in price and footprint. In terms of power and adjustability, the Dado offers up to 10.8 Joules of energy with 12 unique power settings. The MiDi and PulsePoint Studio, in comparison, provide 20 and 30 Joules respectfully but have only nine available power settings. The spot size adjustment options are equal (0.3-1.3mm) for all models and are adjusted manually via a lever or knob inside the weld chamber. The most significant difference remains the price. The Dado sells for USD $4,200. The MiDi and Neutec sell for USD $7,500 and USD $7,995, respectfully. “If I were to simplify the buying decision for budget laser welders, I would group the Dado and the Orotig’s together in terms of features and capabilities,” my long-time colleague, Jonathan Young, said in deep thought. “And in that case, I think the Dado wins in every time based solely on price. If you have the budget to spend more, I will say that buying the LZR35 over the Orotig options is a no-brainer.” What We Can Learn from Orotig If there is anything to be learned from the Orotig lasers, it is that a market exists for that spot between the Dado and high-end models. Shops everywhere will be attracted to a more powerful, more capable model than what the Dado offers, yet less powerful and less capable than what the higher-end benchtop laser welders provide. Enter the Orion LZR35 laser welder from Sunstone. The LZR35 was unveiled at the JCK jewelry show in 2021 and was an immediate success. The LZR35 fits perfectly in Sunstone’s laser product offering, nestled snugly between the Dado and the more powerful LZR75 benchtop laser welder. The LZR35 provides up to 35 Joules of max weld energy and allows for complete customization and selection of both weld power and weld time, resulting in 5,000 power settings versus the 9 or 12 available on the other budget laser welders. The LZR35’s user interface consists of a 7” full-touchscreen display with a digitally controlled, motorized spot size adjustment for precise and repeatable welds. The spot size adjustment ranges from 0.2-2.0mm. The LZR35 looks and acts like its more powerful LZR cousins, given that its feature set closely mimics those found on the higher-powered benchtop laser welders. The only aspect of the LZR35 that can be labeled as “budget” is the price tag: USD $9,900. See the included comparison chart for a complete side-by-side comparison of the LZR35 and the other budget laser welders. What’s the Big Deal? After so many words, my point is simple: Affordable access to advanced welding technologies and robust feature sets has never been greater. Arguably, anyone in need of a budget laser welder can find one that fits their needs, whether based on affordability (Dado at USD $4,200) or on getting the most bang-for-your-buck (LZR35 at USD $9,900).

The data in this table was collected from public sources and is subject to change. Blank cells in the table indicate data that could not be found or verified.

When a critical vaccine must be stored at sub-zero temperatures, Blaze Technical Services rose to the challenge By Andy Jensen In the early months of 2020, the COVID-19 pandemic had the attention of the United States Government. Daily infection rates and subsequent death rates were increasing at an alarming rate. The White House needed a plan that would remove bureaucratic hurdles, provide financial assistance, and pave a clear path for a vaccine to be developed, tested, and distributed as quickly as possible.

The resulting plan was dubbed Operation Warp Speed, taking a page from Star Trek lore to emphasize the plan’s emphasis on rapid progress, with a single objective: Faster approval and production of a vaccine. The plan was bold. And when it was officially announced on May 15, 2020, when 22,845 new cases and 1,367 deaths were reported every day, the United States needed a bold plan. In an opinion piece written by Peter Pitts for The Washington Times, nearly a year later in 2021, Pitts writes, “Operation Warp Speed recognized that all of the members of the health care ecosystem (the innovative biopharmaceutical industry, academia, government, transnational organizations and providers) had to work as a team to solve the many difficult scientific and public health problems created by a new, highly infectious and deadly virus… Warp Speed had to design expedited regulatory review criteria and coordinate manufacturing capabilities on a global scale.” The background behind Operation Warp Speed lays the groundwork and paints the scene for a phone call placed to Blaze Technical Services April 2020. Brian Hickman, the operations manager at Blaze took the call. “The sense of urgency that came through the call was something I’ve never experienced before,” says Hickman. “We were asked to produce a prototype temperature probe under strict confidentiality, and we delivered. Very soon after that we were asked for a thousand, then they would say ‘can you get us 2,000?’ then they’d say ‘can you get us 10,000?” The pressure to manufacture the probe in high numbers was new to Blaze. Brian explains, “We’re not a high production type of shop. We’re a custom shop. The numbers they were asking for were far beyond what we had ever done. We weren’t sure what the probe was for, although we understood that whatever function it provided was considered a national priority.” The team at Blaze began to ramp up production. Immediately they ran into several hurdles, but one in particular threatened the plan for mass production. The probe’s element, the part that measures temperature, was connected to a 24 AWG stranded copper wire with a Teflon jacket. The other end of the wire was connected to a port that would connect to a device that would display, record, or transmit the temperature data. “We needed a stronger weld than what our plasma welders were able to deliver,” says Ralph Hickman, president at Blaze, but an engineer at heart. “When we increased the energy, the heat would melt the Teflon jacket. What we needed was a more focused weld. I was familiar with laser welders and thought it would solve the problem for us. So, I called Sunstone.” The pinpoint accuracy of a laser welder, combined with digital control over the amount of energy delivered and how the energy is delivered was exactly what Blaze needed. “That was half the problem,” Ralph recalls. “Although I knew the laser created a strong weld that didn’t damage the wire’s jacket, I wasn’t sure the laser could stand up to the production numbers I needed. And there was also a concern about operator training. We had very little time to put it all together and a long training curve would not be welcome.” The Blaze team was pleasantly surprised. “The first laser arrived, an Orion LZR 60, and we immediately put it to work. Our team picked it up really fast. It easily kept up with production rates, was highly accurate, and generated little heat,” says Ralph. “We ordered a total of six Orion LZR’s and they did the job for us.” Bryce Bytheway, the laser welding consultant at Sunstone who took Ralph’s order for welders remembers the call. “Frankly, we scrambled to fulfill Ralph’s order for five more laser welders. He made it very clear they needed them immediately. For us it was all hands on deck to make it happen.” With the welding challenge hurdled, the Blaze team still needed to build a high-production assembly line and find suppliers. Ralph calculated that to complete the order for the probe, they would need 3.5 million feet of wire. Of course, he ran into more roadblocks. “Nobody has 3.5 million feet of wire in stock,” he explains. “That’s 663 miles of wire. With the help of my team, we contacted TE Wire and Cable and Dynamic Temperature Supply and told them what we needed. Of course both suppliers laughed at us, which we expected. But after we explained, both suppliers rolled up their sleeves and said, ‘what can we do to help?’” Blaze also had to solve the issue of finding enough elements to fulfill the order. They turned to a supplier based in Germany who demonstrated their commitment by building a new production facility specifically for Blaze. “Every element that facility produced went directly to us,” says Ralph. By August 2020 Blaze was now producing 4,000 probes every day, an impressive number. More impressive was how they got there. “This is a great source of pride for the company,” says Ralph. “I’m proud of our people, very pleased with their effort. They put together a plan and then had an assembly line up and running in ten days.” Hickman, who values a work-life balance, was concerned the project would keep his workers from families but says they were able to keep their over time in check. “We worked a few Saturdays, but my team was able to be with their families. And we couldn’t have done that without the laser welders.” Even before they began full production, Blaze was left in the dark about the probe’s application. While it was clear they played a part in the United State’s efforts to combat the COVID-19 pandemic, how exactly remained a bit unclear. Some members of the team, after reading news articles, speculated the probe had something to do with shipping the vaccine. The vaccine required a storage temperature of -80° F, which fit within the specs Blaze had been given when designing the probe. Not until September 8, 2020, did all the pieces come together. On national television, during a White House press briefing, Ralph and his team saw their probe in full display. “We were under a tight NDA and to see it all shown on national television was interesting,” he recalls. To ship COVID-19 vaccine around the country a special shipping box had to be designed. The fundamental packing isn’t necessarily groundbreaking, but the recording and tracking of the box is new. Dry ice lines all sides of an interior box packed with 1,000 doses, capable of maintaining a -80° F temperature for up to 10 days. If more ice is added, the doses remain viable for up to 30 days, which is key for medical facilities that lack adequate storage freezers. The Blaze probe monitors the temperature surrounding the doses, relaying this data to a minicomputer for storage and transmission. Using a cellular network, the data is transmitted to a central monitoring facility. In addition to temperature, another probe monitors humidity, a GPS tracker provides real time location, and another device records the number of times the box is opened. At any time, the vaccine manufacturer knows the location of any box and its disposition. For Blaze, which manufactured a total of 350,000 probes, the adventure is pretty much over. For Brian, Ralph, and everyone at Blaze, they have a story to tell the grandkids when they are asked about the great COVID-19 pandemic. “It was a surreal experience,” Ralph recounts. “Many times, my team and I were living in the moment and solving problems on the fly. What I saw as a simple business opportunity in the beginning, turned into a fulfilling experience. And we couldn’t have done it without the laser welders.” Brian concurs. “Everyone helped out with production. It didn’t matter what your job title was; we leveraged the individual skill set of every team member to get the job done. You ask any other probe manufacturer if they could do 350,000 probes in a year and they’d balk. We sprinted for a full year and we’re proud of what we accomplished. We could not have done it without the laser welder.” The Sunstone line of Orion LZR benchtop laser welders consists of five different models, each providing a different energy range, from 35 Joules up 180 Joules. The Orion LZR stands apart from other laser welders for its broader feature list, such as on-board HD cameras with an HDMI video port, argon gas connections, compressed air nozzles, larger color touchscreens, and advanced digital interfaces for better energy control. “What I like about the Blaze story is the positivity, the we-can-do-this approach exhibited by the Blaze team,” says Sunstone’s CEO, Jonathan Young. “They came together to solve a national emergency and did so marvelously. I tip my hat to them for what they accomplished. Sunstone sells welders to many different companies who are pushing the envelope in aerospace, electric vehicles, medical devices, and the arts. Many of these stories we can’t share. In this case, with Blaze, when we can share the story, it’s rare and valuable.” How S&S Electronics is Staking Claim in the USD $195 Billion Battery Industry By Andy Jensen The aisle is dimly lit. For unknown reasons, the big box hardware stores are unable to adequately illuminate their wares—except for the lighting aisle, of course. At the moment, I’m investigating battery-powered lawn mowers. Last year, this store displayed only one battery-powered mower. A year later and there are two different manufacturers offering two different models.

What’s going on here? To my right, more battery-powered lawn tools are just as dimly lit. I see a trimmer, an edger, and a leaf blower. I’m not the sharpest tool in the shed, so it takes me half a second to understand all of these tools are powered by the same battery pack. I turn my attention back to the mowers. ‘Would anyone buy a battery-powered mower?’ I think. Then I’m asked to step aside as another customer loads a boxed mower onto a flattop cart. Later, I’m speaking to my daughter on my smartphone. She’s mowing her yard, her first yard, as she just recently purchased her first home. Out of curiosity I ask, “What mower did you get?” Yes, it’s such a dad thing to ask, but super important, regardless. “Umm...” She looks down to see. “It’s a battery mower.” The Race Course Batteries are in high demand because consumers prefer a battery over a gas-powered motor or an inconvenient power cord. Recreational transportation is also fanning the flames. Our urban centers are flooded with electric scooters and bikes. I did a quick online search for “ebike manufacturers” and found a list that included more than 100 manufacturers worldwide. According to a May 2020 report published by Acumen, a research and consulting company, the battery industry will generate revenues of $194 billion US dollars by 2027. Manufacturers are racing to grab a piece of a large pie. The great battery race is a boon for Javier Suniga, a 30-year veteran of the battery world who consults with manufacturers in the design of new battery packs. His company, S&S Electronics, with only 12 full time employees is recognized as a leader in the battery industry. “There’s no shortage of business,” he says. “I’m consulting with aerospace guys and military people who need help in designing a battery to fit in a particular place. I’m helping retail establishments, like Batteries Plus, provide repair services for the mountain of battery packs that are sold with cordless power tools. And on the R&D side, I supply colleges and universities with the parts they need to design a better power cell. And I could tell you how I’ve helped Hyperloop, but we don’t have that kind of time.” A walk through the S&S Electronics facility is fascinating. Aisles hold bins filled with the myriad number of parts that create a power pack: an assortment of plastic containers and metal tabs and connectors of different sizes, shapes, thicknesses, and types of metal. As a metaphor, perhaps S&S is the Amazon of batteries. Whatever you’re looking for, S&S either already has it or they can make it. Organizations come to Javier for help with the design and also in the fabrication. “I provide many companies with pre-assembled components that speed up their manufacturing process,” he explains. “I have the tools that let me quickly create any laser-cut custom tab, something the manufacturer would rather source than create.” Competition is Fierce At one point in his life, a business merger forced Javier out of a company he loved and where he learned the battery trade. “The next day, I backed my car out of my small garage and got to work,” he says with a smile. “I turned my one-car garage into my workshop, my warehouse, and my lab. I’m pretty sure my wife was really happy when the company reached a point when the garage was too small. I guess that was just a perk of success.” Now, as an industry leader, competition comes from a different source. By far, battery packs manufactured in China are attractive to US manufacturers due to price. Javier admits the Chinese battery manufacturers are fierce competitors. “They’re hard to compete against. I understand manufacturers have rigid price points and margins and Chinese prices help them reach those numbers. I can point to quality and transparency as my unique selling point, but that does not always deter a product engineer from going overseas. So, I don’t talk about price, I talk about efficiencies. I can help my customers explore design alternatives that will reduce the number of parts the battery pack requires, which decreases production costs. My ISO certification and reputation help me do what I can to keep US business in the US.” What the Future Holds Javier sees Li-ion as just another steppingstone. “When I got started in this business Ni-Cad was king,” he remembers. “It paved the way for everything to get smaller, especially in the electronics world. Today, Li-ion is the de facto standard. It’s done more for batteries than what Ni-Cad did. But it also has an ugly side.” Javier is referencing the overheating problems the battery faced in its early years. He also recognizes lithium is a rare earth element, which pushes the US market toward dependency on international sources. Lithium also creates an environmental concern. “S&S is not an R&D shop for creating new battery technology,” he explains. “We help customers take existing battery tech and make it work for their products. But the hydrogen technology I’ve seen is impressive. Whether that’s the next step for battery technology or not, I can’t tell you. But I can tell you with certainty, there will be another step. And it will be more revolutionary than ever. That’s very exciting to me.” Welding Technology Spotlight: Sunstone Omega PA250i Sunstone’s new battery welding system is a cardinal welder; a welder of all welders; a welder that all welders aspire to be. The Omega PA250i is packed with versatility and holds a black belt in the martial arts of welding. Let’s start first with versatility. The Omega is not a one-size-fits all answer. The engineers at Sunstone recognized the need for the welder to transform readily to meet the needs of any given organization, or any given department within an organization. That’s why the Omega is available in three different configurations, being able to meet the needs of many different types of shops. For the R&D shop, the Omega provides advanced pulse-arc technology, 5X optics and Sunstone’s lauded digital welding interface. The pulse-arc and optics duo allows any lab to test myriad configurations to find the absolute best welding schedule. For mid-size production facilities, the Omega can be paired with a manually actuated or pneumatic weld head that can keep up with production demands. Of course, the weld head is controlled by Sunstone’s digital welding technology, so operators can expect excellent weld results. For production facilities that are totally automated, the Omega can be paired with a CNC table using the Janome Cartesian Robot. While the Janome takes care of where the weld is placed, the Omega controls the delivery of the weld. The Omega’s versatility makes it a good fit for any type of shop. Or, for larger organizations, the Omega can find a home with the R&D team or on the production floor. Let’s Talk about Features The Omega’s welding performance is made possible by Sunstone’s digital welding interface. A 10-inch color touchscreen allows the operator to control every aspect of the weld, from power to agitation to weld length. After the operator selects the desired attributes, the weld is displayed graphically as a waveform. The operator can see in real time how the weld is affected when different settings are selected. The digital control of the weld is what allows the operator to find, produce, and replicate the perfect weld. Weld schedules can be saved and used for another time. Schedules can also be cloned to another Omega welder in a matter of seconds. The Omega is 100% PLC ready. One or many Omega welders can be controlled from one source, which is perfect for large, automated production lines. One feature some operators will appreciate is the Omega’s on-board automation. Simply select the type and thickness of the metals you’re working with and the Omega will suggest the right combination of settings to deliver the perfect weld. Bread and Butter Features The Omega can deliver up to 250 Ws of energy. The operator can dial in the power down to 1/100th of a Ws. Weld materials between .003-.030 inches (.075-.75mm) in thickness. The operator can store up to 127 different welds with the ability to lock out other operators from making changes to saved welds or the current weld. On a production floor, when operators change from shift to shift, locking the current weld settings provides the company with quality control. Sunstone makes the claim that with the Omega’s digital welding technology any organization can turn to pure copper tabs to boost battery efficiency. “Copper is tricky,” says Thane Kennedy, Product Manager at Sunstone Engineering LLC. “When faced with the challenges of creating battery packs, manufacturers turn to nickel or clad to connect each individual can, because they are relatively easier to weld. The increase in production efficiency is offset by a subsequent degradation in battery efficiency. With the Omega, manufacturers aren’t forced to choose one over the other. They can now weld copper tabs just as easily as any other type of tab and enjoy increased battery efficiency.” As a serious piece of welding technology, the Omega can be protected by a perpetual product protection plan called the Sunstone Circle. As long as you remain a member of the Circle via a monthly subscription, the Omega’s warranty never expires. In the end, the Omega offers a great deal of flexibility tightly controlled by advanced welding technology. By Andy Jensen The economics are simple. Even the most mathematically challenged contractor can understand the attraction. But lest we keep anyone in the dark, let’s review:

A contractor’s best friend is a cordless driver, be it Milwaukee, DeWalt, or Bosch—it’s a personal choice. Fully charged, let’s say a DeWalt can put down 100 wallboard screws with one charge. Now, if a contractor can get another 40 screws out of the same charge, what happens? Those 40 additional screws create a domino effect: Less time spent changing batteries; less batteries to buy; less batteries to charge; and certainly, increased productivity. The single battery pack that came with the DeWalt out of the box was just one of hundreds of thousands built in one Asian facility in a day or two. And it was built by a contractor supplying the same basic battery to several other hand tool manufacturers. Bottom line: there’s nothing special about that battery. If that battery were a college football player, they’d miss the NFL the draft. Just ask Richard Price, a man with more than 30 years of invaluable battery wisdom. With his partner, Frank Ineman, he’s rebuilding battery packs for companies all over North America. “What you get in the box is mediocre,” he says. “But I can take that same battery, rebuild it, make it last much longer, make the customer that much more productive. And I can charge more for the rebuild than buying a new battery because the increase in productivity more than covers the cost of the rebuild. Our customers walk out of our shop with a happy story. It’s the best source of advertising for us.” Frank and Richard’s story is classic American literature. Working for a battery company in the late 1990’s, the two were co-workers at the time, making a living selling car batteries to garages and dealerships. “We were actually doing very well,” Richard remembers. “Between Frank and I we were helping the owner of the company live pretty handsomely. So well, in fact, that he calls me up and says, ‘I’m selling the company!’ Well, that could spell trouble for us. And it did. Shortly thereafter Frank and I are sitting outside the office, out of work. But we were hungry. And I said, ‘Frank, we don’t need him. We can do this ourselves.’ And we never looked back.” The two formed a partnership, rented space, and named the company after Frank’s high school mascot: Bulldog Battery. “We thought it sounded like we meant business, that we had the tenacity to do whatever it takes to keep our customers happy,” Richard says with a smile. “So far, so good.” From the very beginning, Frank and Richard vowed to treat their customers the way they would want to be treated. “We’ll carry a battery to the customer’s car, something you rarely see these days. We believe in offering a level of service and respect that you don’t see any more. Our honest and straightforward way of doing business is what wins over our customers.” The focus on service has worked for Bulldog Battery. Growth has been steady and successful. The company began renting one suite, then two suites, then bought the building in order to accommodate their growth. With 9,000 square feet of space and 12 full-time employees, prospects for continued growth are very good. Bulldog Battery is geared for servicing and solving battery challenges. Whether a customer needs a battery for a laptop, smartphone, electronics, or a custom battery, they can deliver. “We get phone calls from all over the country,” Richard says. “Just last week I got a call from a crane operator in New York. The manufacturer of the crane wanted thousands to replace a battery. We were able to fix it for a hundred dollars. So, he’s thrilled. And once we get a customer, they spread the word like wildfire.” When it comes to batteries, Bulldog has learned that nothing is ever obsolete. Frank and Richard have accumulated the experience to wake up nearly any battery. The company starts with the battery framework. They almost always keep the framework but remove and recycle the interior. “We replace the inside components and are able to increase the run time,” Richard explains. “We make the battery better than it was.” Bulldog Battery can work with any type of battery. And that’s what Richard enjoys about the battery business: never knowing what new battery challenge will walk through his door. For him, going to work is an adventure. “We are always tinkering to find ways to wake up a battery and save our customers money,” Richard says. Micro welding is a crucial to Richard’s ability to find solutions regardless of the challenges that come through his door. A good battery has good energy transfer connections, and a reliable micro welder can make strong, repeatable welds that increase battery efficiency. Choosing the right micro welder that offers a balance between power, precision, and price is very important. More power allows for thicker tabs and connections. More precision allows for truly individualized weld settings based on the application needs. The purchase price of the welder will greatly affect the ROI and profitability of the investment. Luckily, Richard was able to find a micro welding solution that checked all three of these boxes: power, precision, and price. “Our welders let us do things we couldn’t otherwise do,” Richard says pointing to his three Sunstone micro welders. Richard spouts off a long list of different types of batteries he works with, including the temperamental Li-ion. “With the right micro welding technology and skill set there’s not a battery in the world that makes me nervous. We are able to wake up any battery and make it run longer or make it more powerful thanks to having the right tools.” |

Proudly powered by Weebly